TARGUS has received multiple awards for exemplary project work in the past two years. For good reason.

Read as a case study: Good advice alone is not enough. If corporate consultancies want to achieve optimal impact, they must ensure that ideas are successfully implemented for their clients. TARGUS has helped a global pharmaceutical company to greatly increase its market potential by putting recommendations into action. .

If you want to succeed in motorsports, you need to get the horsepower to the road, i.e. convert the full power of the engine into speed. This principle also applies to business: only those who fully utilize their potential can prevail against the competitors in the race for market share and cost leadership. But how do you achieve this?

A global pharmaceutical company and TARGUS customer, faced precisely this challenge in its vitally important North American operation: the output of the plants remained far below potential sales, resulting in back orders and drug shortages, despite around the clock production and state-of-the-art facilities.

The project result: real customer benefit. The organization was transformed using a mobilizing approach. The production and earnings improvements identified in the project were realized – with significantly improved process and product quality.

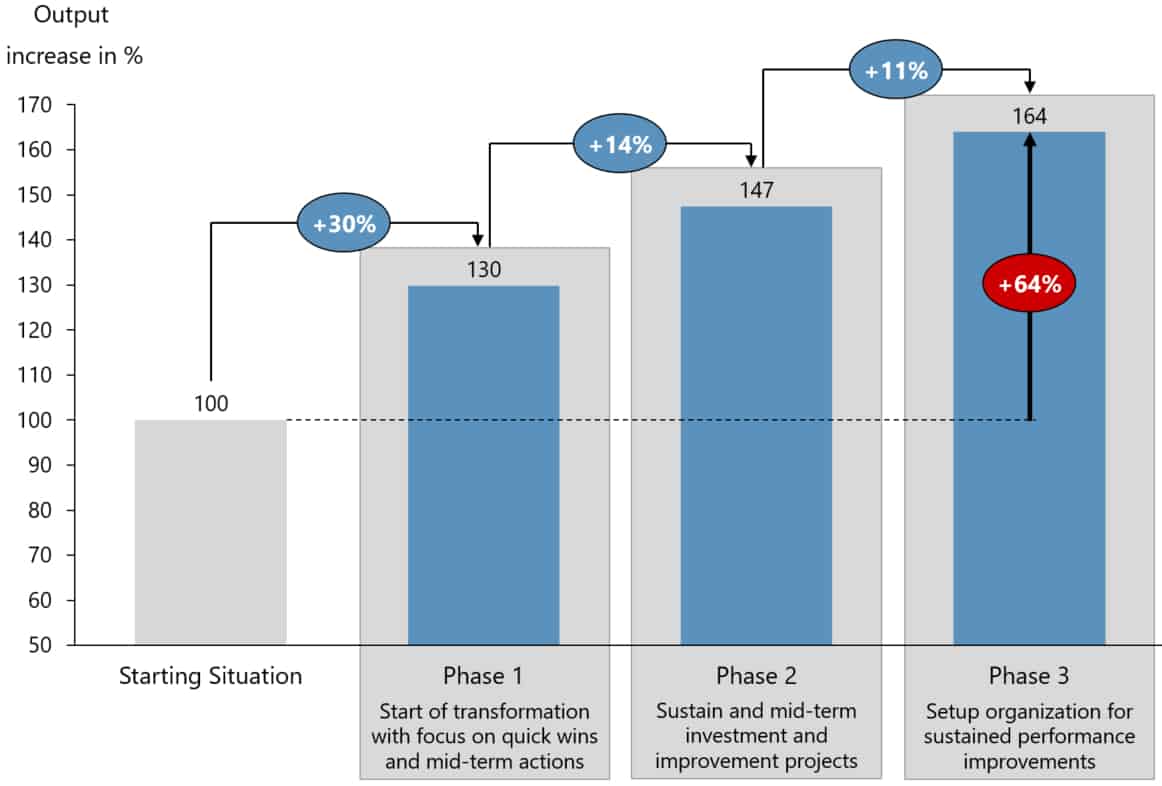

Short-term output increases of 30% and long-term improvements of 64% in a pharmaceutical operations project

To solve the problem, TARGUS and the management team quickly realized that a business transformation was necessary. The consultants used their experience to quickly analyze relevant processes end-to-end to uncover the essential levers of production, always with the focus on the number 1 priority, product and process quality. The key to the transformation lay in identifying, understanding, and constantly visualizing the causes of output losses. By understanding your operations and its weak points, you can improve it – and production will run smoothly.

Assuming a pragmatic approachwhile using the most modern analysis methods, a sophisticated catalog of measures was developed with the managers and employees in production and supporting departments. These were immediately implemented until finally production was running smoothly and at full speed, with the horsepower literally on the road: key technical quick wins that took effect after 6 weeks, medium-term optimizations for the first year and long-term improvement plans.

An important success factor in our implementation is the development of a performance culture, which can only be achieved together with the individual stakeholders. Individual coaching and training sessions were carried out, but management changes also were made.

Technical experts with industrial experience

Consultants often struggle particularly in the disciplines of implementation, and realization of the planned measures. At TARGUS, implementation is part of the DNA: Targonauts, as TARGUS consultants are called, are not satisfied creating clever charts and presentations and giving recommendations to management. Together with the customer’s employees, they also implement the ideas and improvement concepts in the plants until everything works according to plan.

This ability, of course, requires appropriate technical expertise and practical experience of the consultants. This is why most Targonauts have completed a degree in natural sciences or engineering and many have several years of professional experience as line managers, for example plant managers in an industrial company, before becoming a consultant.

Social skills for coaching support

Doers are in demand – not wannabe strategists, but people who are passionate about actively implementing concepts together with the customer, who have an eye for the essentials and get down to business quickly without leaving the team behind. The Targonauts are seen as “helpers” (customer quote) in the project.

The practical experience of the TARGUS consultants also played a decisive role in the case described above. They not only got involved in the analysis and worked with management to develop a detailed Roadmap for increasing productivity consisting of tangible measures with clear responsibilities and binding deadlines, but also acted as part of the implementation team and as pacemakers that employees could use as a guidepost during the turnaround. TARGUS Case Study