Productivity increase (OEE) increases the output of your systems

Availability, performance and quality are the three levers that influence overall equipment effectiveness. The key figure Overall Equipment Effectiveness, or OEE for short, measures the added value of a plant and makes the performance of systems comparable. In order to achieve the benchmarks for plant productivity in industry, the interaction of the complex factors must be optimally designed. With our systematic approach, we show you the levers for increasing the productivity of your system.

Increased productivity with a system

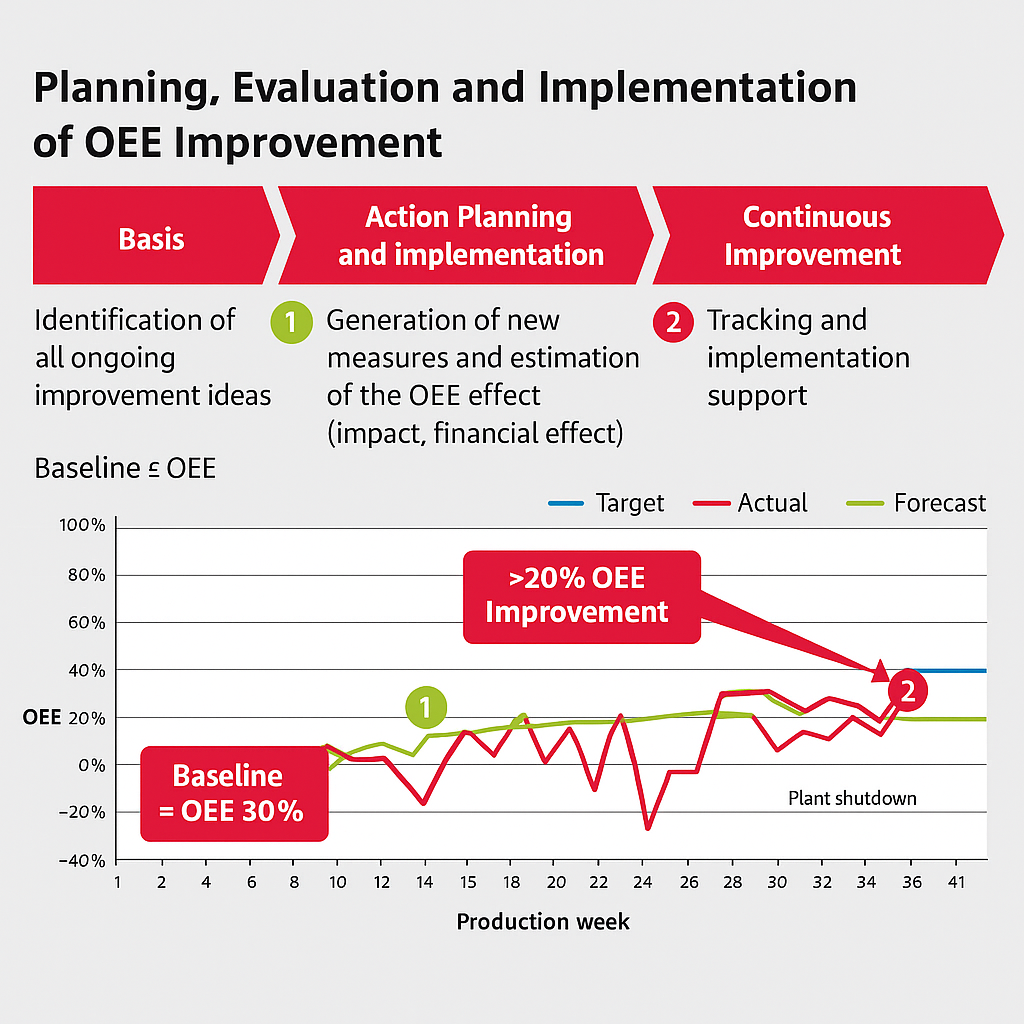

Our goal is not to change one variable, but to significantly improve all three influencing factors of OEE. It is important to discover unplanned downtimes, idle times and quality defects and to determine the causes of them. That’s why we question your processes. The basis for this is our systematic analysis approach combined with the high level of technical competence and many years of practical experience of our consultants.

Productivity increase (OEE) tailored

With our tailor-made concept for increasing productivity, we not only look for starting points to increase performance, but also document, evaluate and prioritize all suggestions for improvement and ideas for your plant effectiveness. For this purpose, we have developed a clearly defined sequence of processes. So können wir sicherstellen, dass jede Idee verfolgt und die bestmöglichen Verbesserungsansätze herausgearbeitet werden.

Individually assembled, interdisciplinary teams from production, maintenance, QM/QA and logistics evaluate each individual idea and determine the expected effect on OEE. Through detailed consideration, we often find exciting solutions. Together with you, we plan the implementation of the measures in detail. The gap detected to the target performance is completely close. The continuous further development and customer-specific adaptation of our measurement and evaluation methods is a matter of course for us.

Typical Results of Productivity Improvement (OEE)

- Increasing production output

- Better availability

- Higher quality

- Reduced downtime

- Better understanding of the disturbance variables

- Defined and measurable ramp-up plan

Productivity increase (OEE) in practice

For a customer in the pharmaceutical industry, we analyzed plant productivity and developed approaches to increase productivity together with the customer’s employees. In addition to the business requirements, the industry-specific legal framework also had to be taken into account. The effect of each individual idea was predicted or determined by means of simulations. Depending on influence and time priority, our consultants implemented numerous individual measures, which also met the official requirements due to the close involvement of the company’s own QA department:

- Maintenance Blitz

- Technological improvements

- Changed break regulations

- Optimal shift staffing

- Controlled set-up processes

- Investment

The sum of many individual projects ultimately resulted in a doubling of the output of the key units and thus a considerable increase in productivity.