Supply Chain & Logistics Screening to address current challenges

Ensuring an economically sustainable and resilient supply chain network is more challenging than ever. Issues are further compounded by an extensive shortage of skilled workers, an exceptional pandemic situation, high customs duties, natural disasters, the volatility of supply chains and the production processes that depend on them.

At the same time, rising logistics and energy costs have a negative impact on a company’s overall profitability. With TARGUS Supply Chain & Logistics Screening, we ensure the necessary transparency in your supply chain and uncover optimization potential. Our aim is to develop targeted measures that can meet current and future challenges.

Supply Chain & Logistics Screening provides an overview of complex structures and identifies areas for action

With our Supply Chain & Logistics Screening, we systematically examine your complex supply chain and logistics processes including the influencing factors.

The relevance of supply chain and logistics management is constantly increasing due to the fast-moving nature of products and the volatility of the market. At the same time, pandemic conditions and a shortage of skilled workers, for example, are acting like a burning glass on supply chain stability. TARGUS Supply Chain & Logistics Screening is recommended to check the robustness and future viability of your supply chain. We use this to systematically examine your complex supply chain and logistics processes, taking into account the various influencing factors.

The TARGUS Supply Chain & Logistics Screening identifies the problem areas and future requirements for a company’s supply chain and logistics, and uncovers optimization potential and organizational bottlenecks. Based on the results of the analysis, our experienced consultants create a concept that includes short-term and long-term measures with detailed opportunity and risk assessments.

Of course, we are happy to provide you with support in implementing the planned counter actions.

A Supply Chain & Logistics Screening tailored to your needs

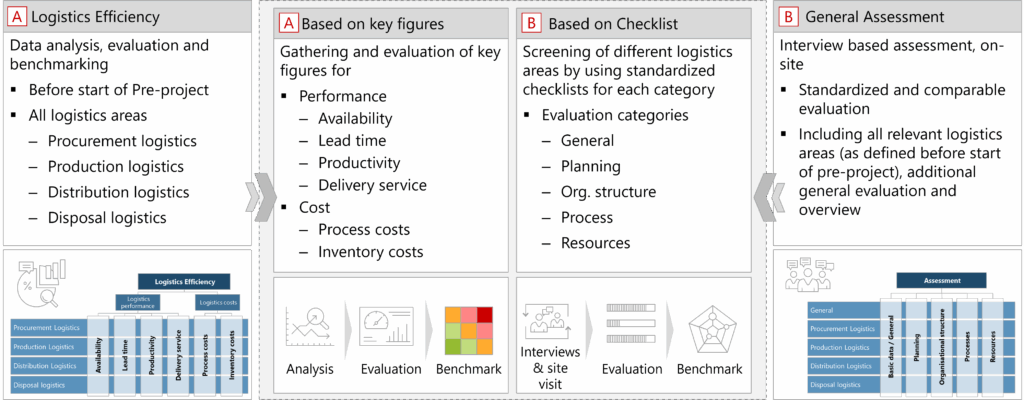

In the run-up to the Supply Chain & Logistics Screening, we work with you to agree the objectives and the area to be examined. For example, in the case of different company locations, we determine those that can generate representative results for the entire supply chain. In order to take the individual circumstances of your company into account, we hold discussions with your employees. It is important to us that not only experts from the Supply Chain & Logistics department, but also from other departments are included in the screening. In addition, selected employees from all locations receive a questionnaire on key processes in the company. This is the only way to identify weak points and uncover relevant correlations. It is important for our consultants to recognize these in the first step of the screening and to describe them based on key figures. In the second step, the consolidated figures, data and facts are used to evaluate the supply chain and logistics performance of your company using the selected areas as examples and to compare them with the strategic requirements. This makes it possible to gain a holistic understanding of the situation and identify which internal and external levers can be used to ensure the performance of the areas under consideration. Our aim is to provide you with tailor-made solutions in the form of catalogs of measures and implementation planning.

Supply chain performance is evaluated in its entirety. On the one hand, quantitative key figures make it possible to benchmark the locations.

In addition, a qualitative assessment is carried out as part of a standardized questionnaire in the following categories:

- IT infrastructure and digitalization

- Planning processes and forecast

- Physical material flow

- Organizational structure

- Resources

Typical Results from the Logistics Screenings

- Reduction of throughput times by up to 45%

- Increase in inventory turnover

- Increased logistic costs control

- Creation of transparency in key performance indicators

- Cost reduction in physical material flow

- Reduction of working capital

- Increase in forecast accuracy

- Improvement of on-time delivery and delivery performance

- Improved distribution of outsourcing & insourcing

- Improved material availability

- Increased supply chain resilience

- Increased economic supply chain sustainability

- Increased level of digitalization