Managing Supply Chain Risks

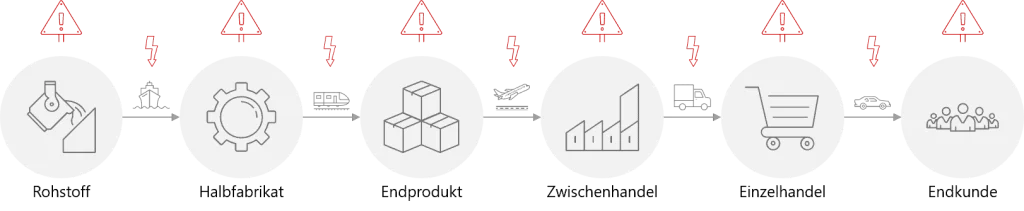

The goal of Supply Chain Risk Management (SCRM) is to ensure continuity of production processes. To this end, companies and their supply chains must be prepared for, and protected against, unexpected events (proactive SC risk management). However, companies cannot counter all risk and must be able to deal effectively with the impacts from supply chain disruptions (reactive SC risk management).

Due to the level of complexity in modern supply chains parts of your chain, which typically recieve little attention, can end up being the source of wide spread disruption. Therefore, the more thorough proactive SC risk management is implemented, the less a reactive SC Risk Management must be.

TARGUS has a long record of successfully implementing SCRM, and can support you in all phases of integration into your organization; introduction, implementation, and optimization.

Effective Supply Chain Risk Management requires a profound understanding of the intricacies and vulnerabilities of your supply chain. A vulnerability check is a systemic review of your supply chain with the targeted goal of revealing vulnerabilities which have the potential for significant disruption to your operations. The typical results of a Vulnerability Check have been described as, “eye opening”.

TARGUS has SCRM experts that can provide a rapid and detailed analysis of your supply chain vulnerabilities.

Preventive Supply Chain Risk Management works to position your SC to be as prepared as possible for future risk. Building a robust supplier chain to stand against external influences, and can react quickly and flexibly to changing conditions. The more pervasive Preventive Supply Chain Risk Management is in your organziation, the less impact a single events can have on your operations. SCRM is an investment in your company’s future on behalf of your customers and stakeholders, the value of which is difficult to quantify and is often underestimated.

The two elements of Preventive Supply Chain Risk Management are:

Detailed Risk Evaluation

The vulnerability check starts by closely examining the known weaknesses of your supply chain.. This can be, for example, the procurement security of critical components along the entire supply chain. If required, the analysis can covers the entire value chain, starting with the raw materials, through to your consumers. At the end of the analysis possible causes of failure, the supply chain structure, and dependencies within the supply chain are analyzed and made transparent.

The result of the risk evaluation is a risk map, including a quantitative assessment of that risk. Providing a prioritization of the risks to countermeasure and recommendations to counter those risks.

Typical results of risk evaluation:

- Order vulnerabilities identified

- Risk drivers evaluated

- Overall risk quantified

Preventive risk minimization

Preventive risk reduction takes the result of the risk evaluation and determines how identified risks are dealt with. Options for dealing with the risks are:

- Eliminate

- Minimize

- Transfer (e.g. to third parties) or

- Accept

From an enterprise perspective, the optimal path is determined for both individual risks and for the overall risk of a company. A well planned implementation roadmap and purposeful control routines will ensure long-term success.

Typical results of risk minimization:

- Dealing with risks defined

- Roadmap for mitigation developed

- Routines implemented

- Further implementation supported (if required)

Reactive Supply Chain Risk Management involves managing disruptions and the additional risk created after an unexpected event has occurred. Effective preventive risk management will reduce the frequency of disruption and amount of effort needed to support your reactive risk management. When you can’t control all risk, effective reactive risk management becomes a necessary proficiency to avert or mitigate further disruption. The key to successful reactive SCRM is detailed planning of effective of measures and rapid implementation.

The two elements of Reactive Supply Chain Risk Management are:

Supply Chain Stress Test

The supply chain stress test analyzes the changes along the supply chain based on a current event or disruption. Customer demand, material supply, and effects on the company are analyzed in three steps. The result of the analysis is a detailed roadmap for closing the current financial year in the best possible way.

Additional information on the Supply Chain Stress Test (LINK)

Typical results of the Supply Chain Stress Test:

- Opportunities and risks assessed as a result of changes in the market and from suppliers

- Recommendations on the actions needed to secure the current financial year

Crisis Management – Supplier Task Force

Crisis Management is the perfect solution for acute disruptions in your supply chain. The first priority of Crisis Management is to create the transparency needed to identify and measure the root cause of change. This is followed by the design of the best solution for your organization, and its rapid and pragmatic implementation. An example of a rapidly implemented solution is, to place a task force directly at a critical supplier’s site to collaborate and secure the material supply on short notice.

Typical results of the supplier task force:

- Create immediate transparency of the situation

- Short-term delivery capability ensured

- Fast practical problem solving on site