Produktivitätssteigerung (OEE) erhöht die Ausbringung Ihrer Anlagen

Verfügbarkeit, Leistung und Qualität sind die drei Stellschrauben, die die Gesamtanlageneffektivität beeinflussen. Mit der Kennzahl Overall Equipment Effectiveness, kurz OEE, wird die Wertschöpfung einer Anlage gemessen und die Leistungsfähigkeit von Anlagen vergleichbar gemacht. Um die Benchmarks zur Anlagenproduktivität in der Industrie zu erreichen, muss das Zusammenspiel der komplexen Faktoren optimal gestaltet werden. Mit unserem systematischen Ansatz zeigen wir Ihnen die Hebel zur Produktivitätssteigerung Ihrer Anlage.

Produktivitätssteigerung mit System

Dabei ist nicht die Veränderung einer Stellgröße unser Ziel, sondern die deutliche Verbesserung aller drei Einflussfaktoren der OEE. Es gilt ungeplante Stillstände, Leerzeiten und Qualitätsmängel zu entdecken und die Ursachen hierfür zu ermitteln. Deshalb hinterfragen wir Ihre Prozesse. Grundlage hierfür ist unser systematischer Analyseansatz kombiniert mit der hohen technischen Kompetenz und langjährigen Praxiserfahrung unserer Berater.

Produktivitätssteigerung (OEE) tailored

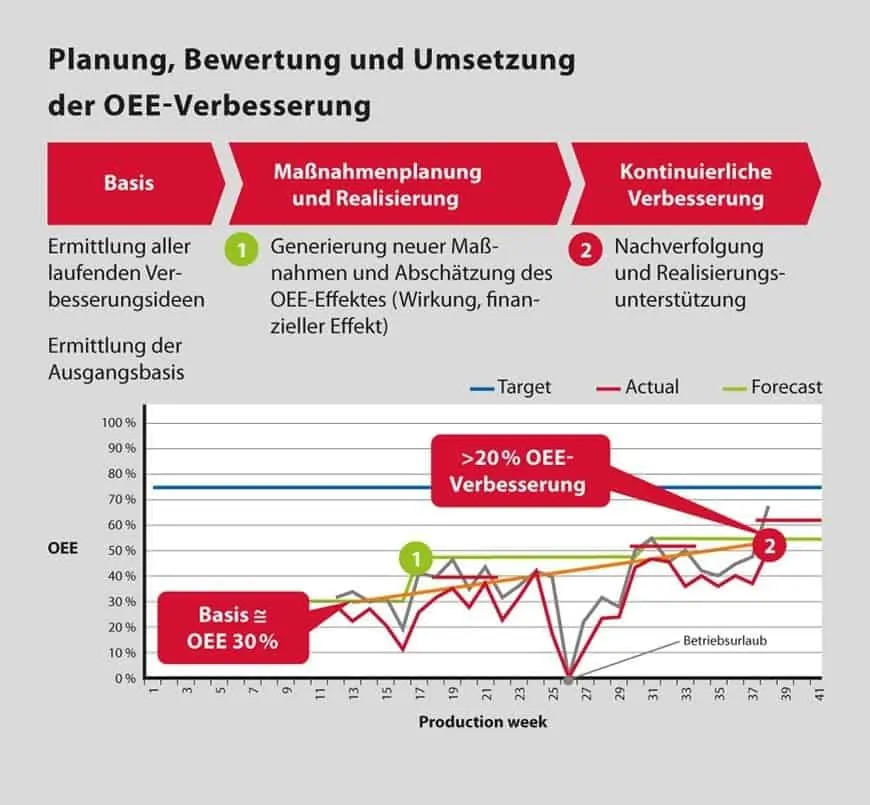

Mit unserem maßgeschneiderten Konzept zur Produktivitätssteigerung suchen wir nicht nur nach Ansatzpunkten zur Erhöhung der Leistungsfähigkeit, sondern dokumentieren, bewerten und priorisieren alle Verbesserungsvorschläge und Ideen für Ihre Anlageneffektivität. Hierfür haben wir eine klar definierte Ablaufreihenfolge entwickelt. So können wir sicherstellen, dass jede Idee verfolgt und die bestmöglichen Verbesserungsansätze herausgearbeitet werden.

Individuell zusammengestellte, interdisziplinäre Teams aus Produktion, Instandhaltung, QM/QA und Logistik bewerten jede einzelne Idee und ermitteln den zu erwartenden Effekt auf die OEE. Durch die detaillierte Betrachtung finden wir oft spannende Lösungen. Gemeinsam mit Ihnen planen wir im Detail die Umsetzung der Maßnahmen. Die erkannte Lücke zur Zielleistung wird vollständig geschlossen. Dabei ist die kontinuierliche Weiterentwicklung und kundenspezifische Anpassung unserer Mess- und Auswertungsmethoden für uns selbstverständlich.

Typische Ergebnisse der Produktivitätssteigerung (OEE)

- Steigerung der Produktionsleistung

- Bessere Verfügbarkeit

- Höhere Qualität

- Geringere Stillstände

- Besseres Verständnis der Störgrößen

- Definierter und meßbarer Hochlaufplan

Produktivitätssteigerung (OEE) in der Praxis

Für einen Kunden in der pharmazeutischen Industrie analysierten wir die Anlagenproduktivität und entwickelten gemeinsam mit den Kundenmitarbeitern Ansätze zur Produktivitätssteigerung. Neben den unternehmerischen Anforderungen waren dabei auch die branchenspezifischen rechtlichen Rahmenbedingungen zu berücksichtigen. Der Effekt jeder einzelnen Idee wurde prognostiziert oder mittels Simulationen ermittelt. In Abhängigkeit von Einfluss und zeitlicher Priorität setzten unsere Berater zahlreiche Einzelmaßnahmen um, die durch die enge Einbindung der werkseigenen QA-Abteilung zudem den behördlichen Vorgaben entsprachen:

- Maintenance Blitz

- Technologische Verbesserungen

- Geänderte Pausenregelungen

- Optimale Schichtbesetzung

- Geregelte Rüstprozesse

- Investitionen

Die Summe vieler Einzelprojekte ergab schließlich eine Verdoppelung des Outputs der Schlüsselaggregate und somit eine erhebliche Produktivitätssteigerung.