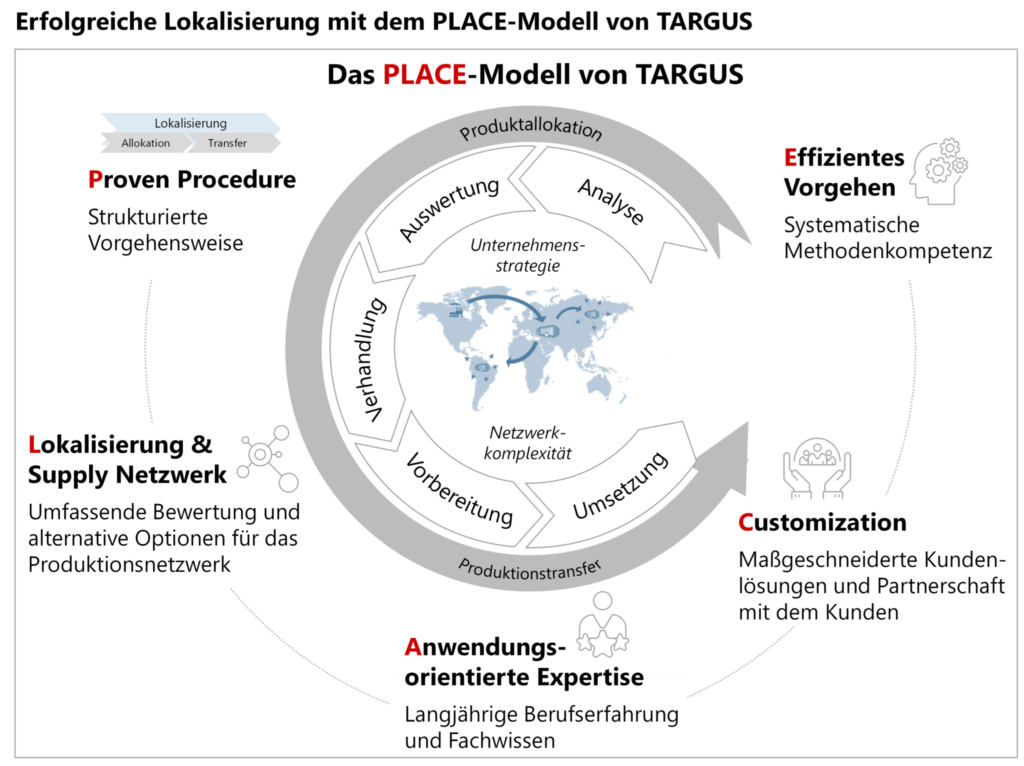

Successful localization with the PLACE Model by TARGUS

Numerous triggers can force companies to react to market volatility and redesign their production networks. The most common reasons to rethink the current configuration of your own production network include:

- Demographic change,

- Scarcity of resources (material and know-how availability),

- Increasing cost and competitive pressure,

- Increasing cost and competitive pressure,

In globally interconnected supply networks, pandemic situations and measures to contain them, political measures such as punitive tariffs on certain goods and armed conflicts sometimes have serious effects on the own value creation processes.

Therefore, parallel to the globalization of production, the trend towards reshoring, i.e., the formation of regional value creation networks, is also intensifying. With the PLACE model developed by TARGUS, we offer you a proven concept for optimizing your localization projects.

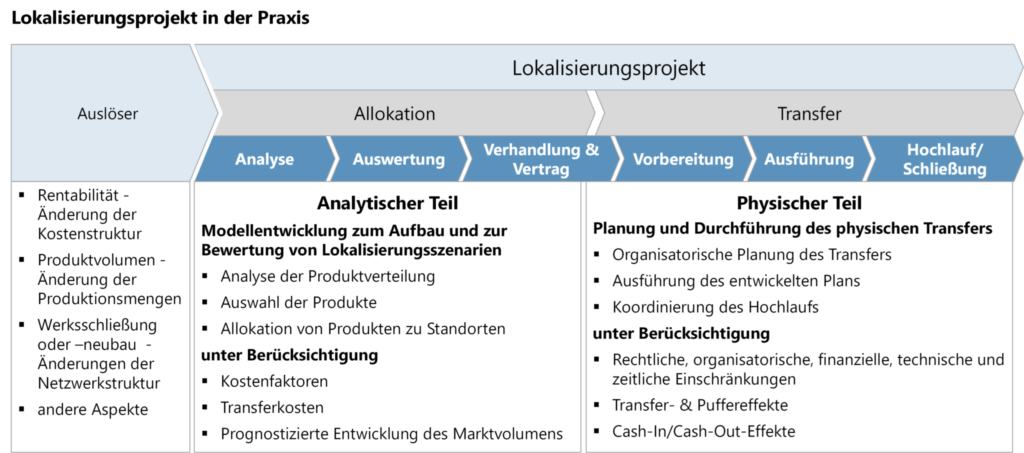

The efficient realignment of your products within the network through allocation as well as the relocation of production facilities or entire locations are in the focus of localization. It thus primarily comprises plant and product relocations, mergers, and relocations as well as outsourcing and insourcing of production.

Typical Starting points for Localization Projects

- Which strategic orientation is the right one for the production network in the future?

- Which products should be produced at which locations?

- What roles should the individual locations play and where should they be located?

- How much capacity should be allocated to each site?

- Which markets should the individual locations serve?

- How can synergy effects be achieved at the locations?

- How can a location be relocated optimally and efficiently?

Personnel Costs as Main Trigger for Localization

Western European production sites have become increasingly important in the network structure of internationally active companies in recent decades. For 71% of the production relocations abroad, personnel costs were the dominant motive. n addition, the introduction of the minimum wage has further intensified the cost pressure on companies. While the outsourcing targets of many companies were initially in countries such as Poland, the Czech Republic or China, some companies went one step further. A trend in the field of localization shows that production is being relocated from the previous target countries to countries with even cheaper production opportunities such as Romania, the Dominican Republic or Egypt. But in the meantime, an opposite tendency can also be observed. Selective punitive tariffs imposed by individual countries, the corona pandemic and armed conflicts have led, among other things, Selective punitive tariffs imposed by individual countries, the corona pandemic and armed conflicts have led, among other things, to companies increasingly reshoring and relying on more local production networks. All of these new production relocations pose major challenges for companies.

The PLACE-Model provides Security for High-Risk Localization Projects

The often historically grown network structures, strategic decisions through mergers & acquisitions or the volatility of the markets create a need for action to realign the production networks. Decisions to relocate pose major challenges for companies: they are always risky and can even threaten the existence of an entire company in individual cases. Because an unplanned standstill of production can quickly cause considerable costs and irreparable damage to the company reputation.

With the PLACE model, TARGUS has created the opportunity to significantly increase the probability of success of industrial transfers through localization. Various control levers are used for this purpose:

- Creating transparency

- Finding optimal target achievement

- Ensure the implementation of project planning

- Enable flexibility

A methodological core element of the model is the approach developed by TARGUS for the development and evaluation of localization scenarios. During the planning and implementation of the physical transfer, a detailed quality management system consisting of detailed checklists with quality gates, various methods from the field of project management as well as field-proven TARGUS methods and analysis tools contribute to success.

Localization tailored

Our experienced management consultants have developed the PLACE model for companies that want to examine or are planning to relocate their production. The PLACE model serves as a method to analyze the individual challenges from allocation analysis to the actual production transfer and to minimize the risks of localization through a clearly defined approach.

Proven Procedure

Includes the detailed localization process, which consists of two parts: allocation as an analytical part and transfer as a physical part. The deductively constructive process offers the possibility of a strong detailing of the individual phases, which can be used individually in projects. Checklists and quality gates are used, which are also used for goal-oriented reporting and monitoring.

Localization and supply network

The PLACE model supports the systematic development of various localization scenarios and examines alternative options for the production network. Therefore, specific premises of the future network configuration are developed and evaluated. This enables the subsequent assessment and selection of the scenarios, considering a comprehensively coordinated target system that maps the corporate strategy and network complexity.

Application-oriented Expertise

Stands for our many years of experience and expertise in the field of localization. Consultants at TARGUS are implementation managers who have already planned and implemented several localization projects, even in difficult environments. We control the optimization of your production networks with our transparent monitoring in a focused and implementation-oriented manner.

Customization

Based on our many years of versatile project experience as well as our systematic methodological competence, we can develop and implement tailor-made solution concepts for our customers. This is the prerequisite for our successful localization solution concepts.

A trusting partnership characterizes the cooperation between TARGUS and its customers during the localization project. We do not see ourselves as an ordinary consulting service provider who merely proposes a concept for a new strategy. We also accompany our customers in the project from A to Z and at the same time support them comprehensively from the management to the process level.

Efficient approach

Describes the analytical method strength of TARGUS management consultants. With professional project management, we systematically and selectively use various field-proven analysis methods and tools in the context of localization, which are summarized in our TARGUS toolbox. We also develop project-specific tools that are adapted to the individual requirements and tasks of your company.

As an experienced implementation manager with excellent methodological competence, TARGUS ensures efficient planning and implementation of your localization project:

- Support from the management to the process level

- Method strength from strategy to implementation

- No use of standard solutions, but customer-specific problem solving

- High-implementation, focused control

- Transparent project management and monitoring

With the PLACE model, we offer you a proven implementation concept for your localization projects. We uncover risk factors, accompany you in the transfer preparation and implementation and ensure a high-quality project process.