Effective supply chain management

Even the absence of a single component almost inevitably means that the finished product cannot be produced in the planned time. Depending on the buffer time, the agreed delivery date can often not be met – with the consequence of additional costs and recourse claims. If the reserved space in the assembly chain can no longer be filled by rescheduling, it is irretrievably lost for the optimization of capacity utilization.

This is especially true for companies that manufacture their products in highly customized variants, each with small quantities. Consequently, controlling the supply chain with up to several hundred suppliers is a highly complex task. The complete monitoring of all suppliers is simply not possible.

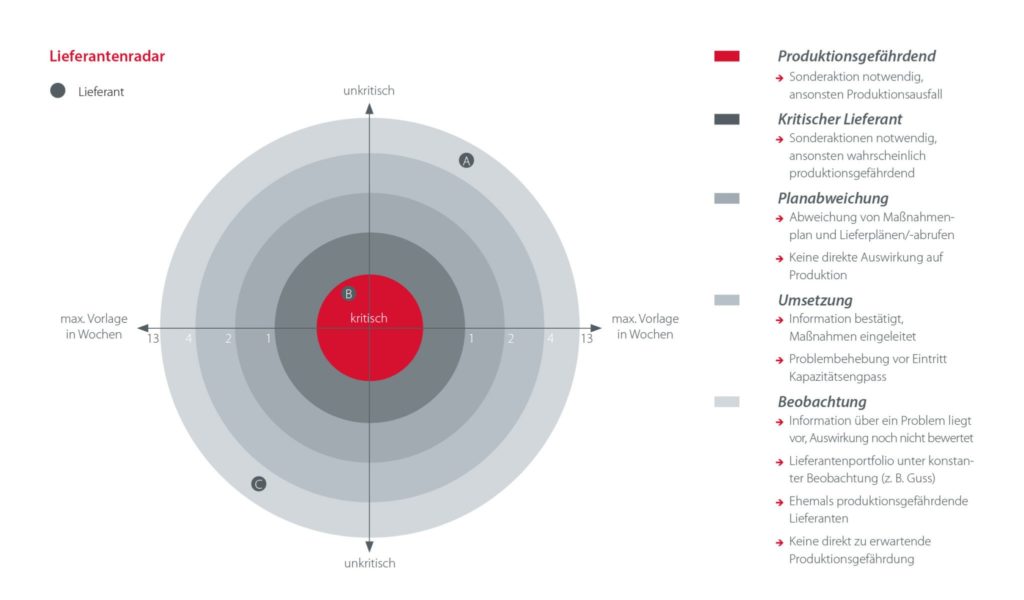

Supplier radar

Project outcomes

- Reduction of incidents by 37%

- Increasing the visibility of problems in the inflow

- Expansion of the short-term visibility of the material flow

- Improvement of the unrest costs related to suppliers by 43%