Successful development PCO with interdisciplinary teams

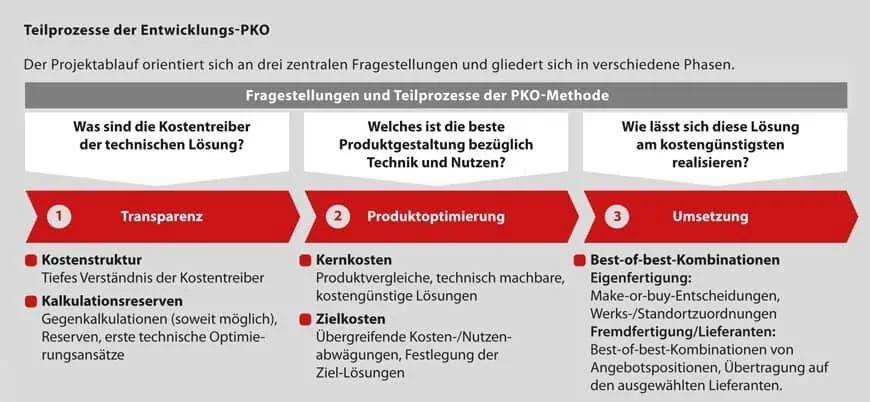

Product cost optimization is based on transparency of forecasted manufacturing costs, sales prognosis, customers and their requirements for the respective products. Working from the cost structure interdisciplinary teams from Development, Procurement, Production and Sales/Marketing determine first the minimal/core costs to achieve the desired function. In the next step the differentiation characteristics and additional value are evaluated. These mean indeed additional costs, but on the other hand also yield a larger market, competitive advantage and therefore margin/profit potential. In addition in a development PCO competitors‘ products are analyzed and suppliers are included in the process in joint workshops.

After deduction of core costs, the physical/technical cost minimum relating to the optimal production process and product design, then client wishes can be represented also as surcharge item and applicable optimization measures for product configuration can be developed. The core costs allow additionally for a structured dialog of the affected departments in which the internal investments can be compared to evaluated potential savings.

Development PCO tailored

No matter how varied the products we can establish the individual core costs of each of your products using our special Product Cost Optimization approach. Using our development PCO approach we discover hidden potential and put a price tag on each possible action. The measures for cost optimization are determined together with all departments and can be followed though a tracking system.

Typical results from development PCO

- Potential savings of the core costs of 30-40%

- Reduction of product costs by 10-20% for current products

- Increase in process efficiency

TARGUS was asked to reduce manufacturing costs by at least 10% for an engine manufacturer whose in-house investigation only revealed a cost savings potential of 5%.

As a first step sales projections were reviewed and the manufacturing costs of the product were broken down into material amounts and processing steps. Each material was accompanied by a possible action. Parallel to this our PCO experts investigated similar products of 3 competitors for constructive solutions and other production methods and generated a detailed off-set calculation. Based on the results of the calculations discussions were held with selected suppliers about potential savings.

Together with suppliers, R&D, Production and Procurement not only were the product and product costs optimized but also the production was simplified. Thus using R&D-PCO a savings potential of 10% was achieved in the first year and in the following 2 years an additional 10% was achieved.