Lean Overhead requires Communication

Effectiveness and/or efficiency improvement are the motivation for Lean Overhead, the streamlining of the organization. Decisive for success is the early buy-in of management and affected employees. As a leading management consultancy we optimize therefore not only your processes but also develop with you a transparent communication strategy.

Lean Overhead produces a more efficient organization

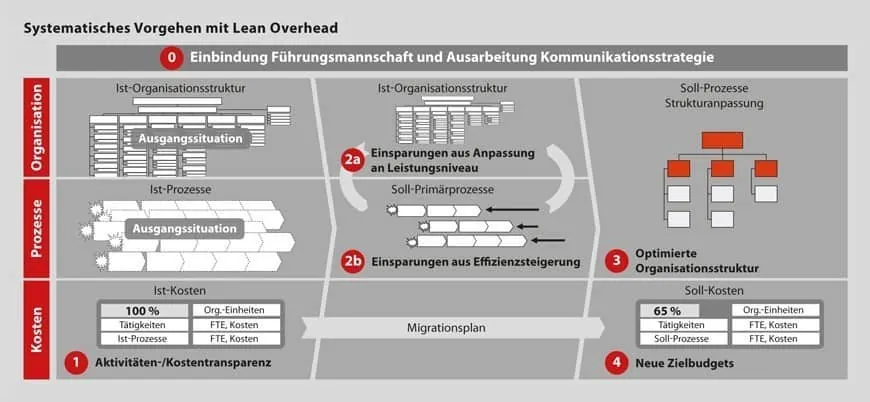

Modification of performance based on changing factors and the optimization of the processes are the essential levers for a sustainable reduction in overhead costs. First a detailed analysis of the current situation is conducted. All inspected activities are included in a functions matrix, processes are analyzed and material costs are examined.

Through the detection and elimination of non-valued-added activities the scope of work is reduced to its essentials and effectiveness is increased. For additional efficiency improvements our experienced management consultants prepare suggestions to optimize your processes and internal communication. In the last project phase of Lean Overhead a new target organization is prepared with appropriate budgets. We support you in the objective and personnel implementation of the planned measures.

Because of cost reductions by their main competitors as well as increased cut-throat competition from non-European competitors our client lost its market leading position in Europe. Using the Lean Overhead method our management consultants were able to reduce overhead (labor and material costs) across the board at all locations by 20%.

Lean Overhead tailored

Resistance reduces greatly the success of Lean Overhead projects. Employee communication is therefore an essential part of the TARGUS Lean Overhead projects. Already before the start of the project we develop with you a personalized communication strategy for your company. Comprehensible reasons and clear goals by management are key factors for success of the project. Through the early integration of management we increase acceptance and speed of implementation and achieve the desired results.

The individual concepts and measures are compelling, innovative and designed to ensure rapid implementation. Because of cost reductions by their main competitors as well as increased cut-throat competition from non-European competitors our client lost its market leading position in Europe. Using the Lean Overhead method our management consultants were able to reduce overhead (labor and material costs) across the board at all locations by 20%.

Typical results of Lean Overhead

- Cost reduction through detection and avoidance of non-value-added activities

- Efficiency increase through streamlining of existing processes

- New development of efficient business processes

- Reduction of overhead costs by up to 30% (labor and material costs)

Cost reduction and new areas of growth

Due to massive cost reductions leading market share was regained and additional new areas of growth outside of Europe were achieved.

At the start of the project a communications strategy was developed. Employees and the media were informed about the reasons and goals of the project using various media (network, notices, press releases). At the same time our consultants determined with our client the scope of the project and the function matrix. Analysis units were established. After identification of activities, potential savings were determined, entered into a data bank and milestones were established. After a detailed analysis of the primary processes the process flow and degree of automation was optimized. An examination of material costs achieved additional savings.